Advancing the frontiers of physics at Wright Lab through advanced prototyping

Students using the capabilities of the APC. Credit: Yale Wright Laboratory/Victoria Misenti

The Advanced Prototyping Center (APC) at Yale Wright Laboratory (Wright Lab) has provided an advanced fabrication facility and design support for custom instrumentation within the Yale community since 2018. The APC was started to extend the capabilities of the machine shops at Wright Lab, which provide traditional machining services and training. The APC has been a trailblazer for Yale’s instrumentation initiative, and its success has contributed to the development of the new Advanced Instrumentation Development Center (AIDC), which is expected to open in fall 2026.

A rendering of the future AIDC entrance lobby.

The AIDC will be a hub for research instrumentation efforts at Yale University. It will build upon the Wright Lab Advanced Prototyping Center and create new spaces for the design, fabrication, and testing of novel research instrumentation. The AIDC, now under construction as part of Yale’s Upper Science Hill Development project, is an important element of one of the cross-cutting priorities identified in a report issued by the University Science Strategy Committee. Karsten Heeger, Eugene Higgins Professor of Physics and Wright Lab director, is co-chair of the AIDC Planning and Transition Group; along with Lisa D’Angelo, Associate Provost for Research.

A few examples of Wright Lab research programs that have been supported by advanced prototyping and instrumentation development are described below. Yale community members interested in learning more about using the advanced prototyping capabilities at Wright Lab for their research should contact Craig Miller, Research Shop supervisor and APC manager.

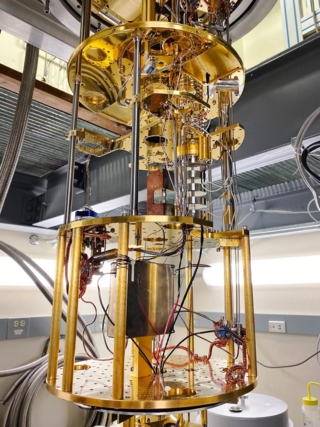

The inside of the HAYSTAC experiment’s dilution fridge. Credit: Yale Wright Laboratory/HAYSTAC

The HAYSTAC and ALPHA experiments, both located at Wright Lab, use quantum and microwave technologies to search for a hypothetical dark matter candidate—a very low-mass particle called the axion. Steve Lamoreaux, Eugene Higgins Professor of Physics, and Reina Maruyama, professor of physics, are the principal investigators (PI) of HAYSTAC; and Maruyama is the spokesperson of ALPHA.

The shops at Wright Lab have supported the fabrication of critical components for the HAYSTAC and ALPHA experiments. Advanced prototyping equipment, especially the water jet cutter, was crucial to allow rapid progress in building the HAYSTAC system.

Maruyama explained, “Having on-site shops is critical in allowing us to design these experiments. We are able to design better components and ultimately build better experiments because we are able to have rapid back and forth conversations with the technical staff.”

Maruyama continued, “The capabilities and guidance from the APC are especially valuable to our students and postdocs, who were enabled to design, build, and install experimental hardware; making important contributions to the experiment’s success.”

Current Axion Dark Matter at Yale researchers include: Keith Baker, D. Allan Bromley Professor of Physics; Sean Barrett, professor of physics; Charles Brown, assistant professor of physics; Heeger, Konrad Lehnert, Eugene Higgins Professor of Physics; Lamoreaux; Maruyama; Michael Jewell, associate research scientist; Maximiliano Silva-Feaver, Mossman Fellow; Tyler Johnson, postdoctoral associate; and graduate students Xiran Bai, Eunice Beato, Eduardo Castro Muñoz, Eleanor Graham, Claire Laffan, and Sukhman Singh.

Developing precise techniques to search for new physics

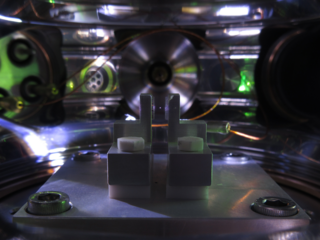

Nanoparticle trapping mechanism for SIMPLE. Credit: Yale Wright Laboratory/SIMPLE/Tom Penny

SIMPLE and QuIPs are two tabletop experiments at Wright Lab led by David Moore, associate professor of physics, that use lasers to levitate, control, and measure micron-sized spheres (“microspheres”). By measuring the motion of the microsphere, the group can precisely detect extremely tiny impulses (smaller than 1 quadrillionth of the momentum transferred by a feather landing on your shoulder).

With the support of the advanced prototyping equipment at Wright Lab, the Moore group has developed the world’s most sensitive micron-sized force sensors to study interactions involving neutrinos; to test gravity; and to search for dark matter, quantum phenomenon, sterile neutrinos, and new forces.

The Moore group used the APC’s laser cutter for the optics enclosures and the water jet cutter to make a vacuum chamber.

Moore said, “The combination of Wright Lab’s onsite research and professional shops with the complementary APC allow us the flexibility to create any part we need for building instruments in our lab. These tools are really crucial because we are building instruments that don’t exist anywhere else and require a huge number of custom components.”

Current SIMPLE/QuIPS researchers include: Moore; postdoctoral associates Lucas Darroch and Aaron Markowitz; and graduate students Jackie Baeza-Rubio, Cecily Lowe, Siddhant Mehrotra, Ben Siegel, Yu-Han Tseng, and Molly Watts.

Optimizing advanced detectors for neutrino research

Liquid xenon R&D setup at Wright Lab.

The Moore group also has used the APC’s ultra-precise orbital Tungsten Inert Gas (TIG) welding to build a new cryostat for research and development (R&D) for next-generation neutrino experiments.

The cryostat is used to acquire ultrapure liquid xenon—the current supply of which is extremely limited— by trapping it optically. Xenon is used as a medium to slow down the particles that pass through, making it more possible for the detector to detect processes such as neutrinoless double beta decay, which, if found, could answer why we live in a Universe of matter, not antimatter.

Moore said, “These fully custom, world-leading instruments are only possible to build with access to these resources.”

Darroch said, “We encounter novel problems on a day-to-day basis in experiment physics. Our research requires rapid iteration on the design of our instruments, such as welding cryogenic plumbing on one day and machining bulk heads for a vacuum chamber on another. The APC enables us to solve these problems as fast as we encounter them, which means we spend more time in the lab and less time waiting for parts to arrive.”

Current researchers working on this R&D project include: Moore; Darroch; and graduate students Glenn Richardson, Watts, and Sierra Wilde.

Assembling components for international neutrino experiment

The Heeger group will use the Deep Underground Neutrino Experiment (DUNE), which is currently under construction, to study the parameters that determine the matter-antimatter imbalance in the Universe and the ordering of neutrino mass states. DUNE will send a high energy neutrino beam through the Earth’s crust over a distance of 1,300 kilometers from Fermilab in Illinois to the Sanford Underground Research Facility (SURF) in South Dakota to perform precision studies of neutrino oscillation.

Yale is one of two key US assembly and testing sites for DUNE’s charge readout planes (CRPs). These large detector elements are critical to the DUNE Far Detector system; recording and reading out the charged signals from particle interactions.

The Heeger group used the APC’s laser cutter to make acrylic guards and tooling tables where visual access to the bottom of the detector assembly is needed.

Additionally, the group used the APC’s water jet to make intricate aluminum parts for bases, frames, and similar elements; which would not be cost effective with traditional machining.

James Wilhelmi, engineer, said “The ability to rapidly and accurately produce parts with intricate geometries and hole patterns in a matter of minutes rather than days has consistently allowed us to adapt our tooling as needed without delays.”

The current DUNE team includes: Heeger; research affiliate Sandro Palestini; Wilhelmi; postdoctoral associate Tyler Stokes; and graduate student Rohit Raut.

New detectors for the CERN Large Hadron Collider

ATLAS Stave core being tested in a Wright Lab clean room. Credit: Yale Wright Laboratory/ATLAS

Paul Tipton’s group is using ATLAS— a detector installed in the Large Hadron Collider (LHC) at CERN in Switzerland—to test the Standard Model of physics and search for new physics. To enable this research, the group is constructing critical elements for an upgrade of the ATLAS tracker, called stave cores. The stave cores are the structures that will hold the detector’s sensors, while maintaining a controlled temperature. Each stave core will have 28 thin silicon-wafer strip particle detectors mounted on it. Staves will reside in the central (barrel) region of the new tracker.

The ATLAS team manufactured customized tooling for stave core production using 3D Printing at the APC. In order to be able to test the specifications of the produced stave cores, the team built a new thermal enclosure. The APC laser cutter was used for complex geometries in the enclosure, such as the access door, cooling line panel, and IR camera stand.

Tipton said, “The in-house manufacturing process ensured a tighter quality control environment [than the previous testing setup the group had been using], providing the stability required for accurate stave core testing.”

Brandon Ramirez, technician, said, “Access to the APC’s infrastructure has allowed us to rapidly modify and manufacture tooling, greatly shortening turnaround times, which has proven critical for meeting the demands of our R&D work.”

Current ATLAS team members working on the stave core upgrade are: Tipton; Jeffery Ashenfelter, associate director for Wright Lab operations; Mark Haeckel, research & development technician 3 - mechanical technician; Tom Hurteau, research & development technician; Ramirez; postdoctoral associate Elise Le Boulicaut Ennis; graduate students Arianna García Caffaro and Jesse Farr; and undergraduate Laec Lorentzen.

Understanding dark energy and its effect on the expansion of the Universe

Mark Haeckel (L) and Tom Hurteau (R) working on QUEST in a Wright Lab clean room.

The group of Charlie Baltay, Eugene Higgins Professor Emeritus of Physics, recently upgraded the QUEST camera with the support of the APC. The QUEST camera, originally constructed at Yale, has been used in a variety of surveys over the years and is currently being re-installed for the La Silla Schmidt Southern Survey (LS4).

The Baltay group uses QUEST to observe supernovae and variable stars as calibration standards. Their work has improved the precision of the Hubble constant measurement such that it is now better than the unexplained discrepancies.

The group used the water jet in the APC to fabricate the intricate details of the camera’s confocal plate that accurately positions each CCD (charge-coupled device) sensor, cable extension slots for readout electronics, and the filter tray.

Baltay said, “The excellent facilities and expert engineering and technical resources at Wright Lab—including the APC, machine shops, and clean rooms—made the successful completion of this construction possible. Our group is grateful for all the support and collaboration provided by the Lab.”

Wright Lab QUEST team members include: Baltay; David Rabinowitz, retired senior research scientist; Will Emmet, senior mechanical engineer; and Hurteau.

Technical staff support

Frank Lopez (L) and Pranjal Tiwari from Bluefors (R) installing the ALPHA dilution fridge at Wright Lab.

Also essential to the success of these projects and the APC is the support of Wright Lab’s technical staff, who are not assigned to any one project but rather support all of them.

Frank Lopez, research & development technician further explained, “Not only does our technical staff support the APC, but the APC supports our technical staff. It’s a circular system that works well in our effort to provide for the needs of our research community.”

Wright Lab’s technical staff includes: Ashenfelter; Vincent Bernardo, director, J.W. Gibbs Machine Shop; Miller; Thomas Barker, electrical engineer; Haeckel; Hurteau; Lopez; Michael Nuzzo, technician; Ramirez; Dylan Vansteenbergen, research & development technician, machine shops; and Wilhelmi.